Laser cutting wood has transformed how creators, designers, and businesses bring ideas to life, enabling intricate cuts and engravings with exceptional precision. From home-based crafters to professional manufacturers, laser cutting technology empowers users to create detailed wood projects that require minimal finishing. This guide explores everything you need to know about laser cutting wood—from the basics of how it works and the best wood types to use, to essential tools, safety tips, and creative ideas that can inspire your next project.

Table of Contents

ToggleWhat is Laser Cutting, and How Does it Work?

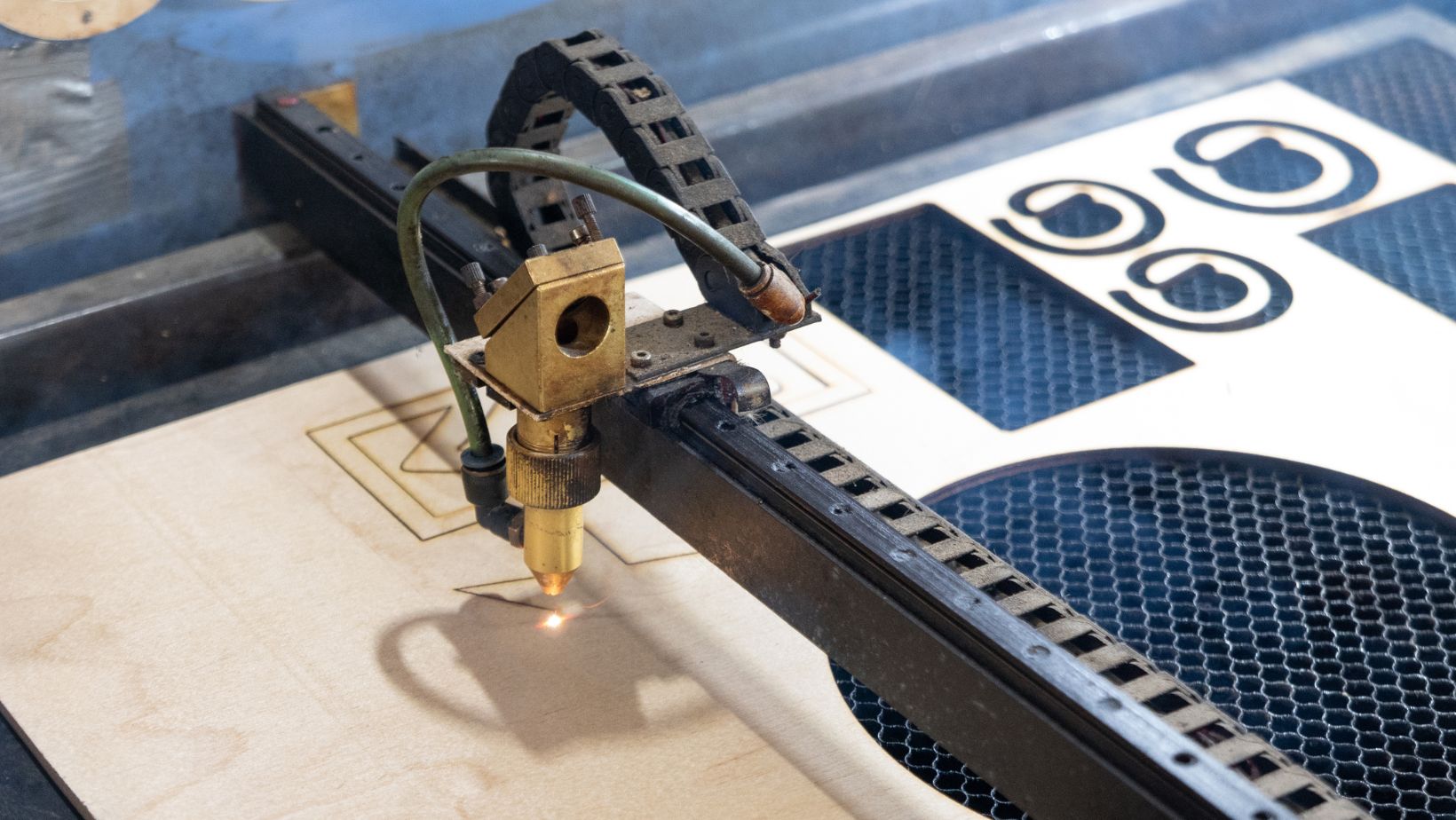

Laser cutting is a precise technology that uses a concentrated laser beam to either cut through or engrave materials like wood. In this process, a laser beam is focused onto the wood’s surface, vaporizing or burning the material along a designated path. This approach results in detailed cuts or engraved designs that require little or no further finishing, thanks to the laser’s accuracy.

In wood laser cutting, two primary techniques are typically used: cutting, where the laser beam penetrates the wood entirely, and engraving, where the beam etches a design onto the surface without cutting through it. Both methods are capable of producing intricate designs, making laser cutting an ideal choice for creating custom, unique, or personalized items from wood.

Benefits of Cutting Wood with Laser

Laser cutting wood offers a range of advantages, from its speed and precision to the high level of control it provides over complex designs. One of the major benefits is the smooth, polished edges that laser cutting achieves, which eliminates the need for additional finishing.

Because laser cutting allows for very intricate detail, it’s suitable for projects requiring precision that would be challenging with traditional cutting methods. This technology is versatile and applicable to everything from custom home décor and jewelry to signage and industrial components. For those running a small business, laser cutting wood also provides a scalable method to ensure quality consistency, making it perfect for both limited-batch and mass-production needs.

Types of Wood Suitable for Laser Cutting

Different types of wood react uniquely to laser cutting, so choosing the right wood depends on the project, budget, and desired outcome. Plywood is a popular choice due to its affordability and versatility; it’s available in various thicknesses, making it suitable for both cutting and engraving. However, some plywood contains glue layers that can emit fumes or affect cut quality. Hardwoods like maple, cherry, and oak are known for their durability and attractive finish, making them excellent choices for high-end projects, though they require higher laser power because of their density.

Softwoods, such as pine and cedar, are easier to cut and are typically more affordable but can sometimes produce a slightly charred edge, especially on thinner sheets. MDF, or medium-density fiberboard, is another budget-friendly option that has a smooth and consistent surface, making it ideal for engraving.

However, it contains resins that may produce additional fumes, so adequate ventilation is essential. Bamboo, valued for its sustainability and unique look, is dense and requires slower cutting speeds but produces a clean, distinct finish. Choosing the right wood type enhances the quality of your project, and for more insights into wood engraving, you can explore xTool Academy’s guide to wood laser engraving for helpful techniques and tips.

Recommended Laser Machines for wood-cutting

Selecting a high-quality laser cutter is essential for those serious about working with wood. An ideal laser machine balances power, precision, and versatility, allowing users to create clean and consistent cuts across various wood types. xTool offers several well-regarded laser machines designed specifically for wood cutting and engraving.

The tool D1 Pro is known for its high-precision diode laser, which is ideal for intricate wood engravings and can handle different thicknesses.

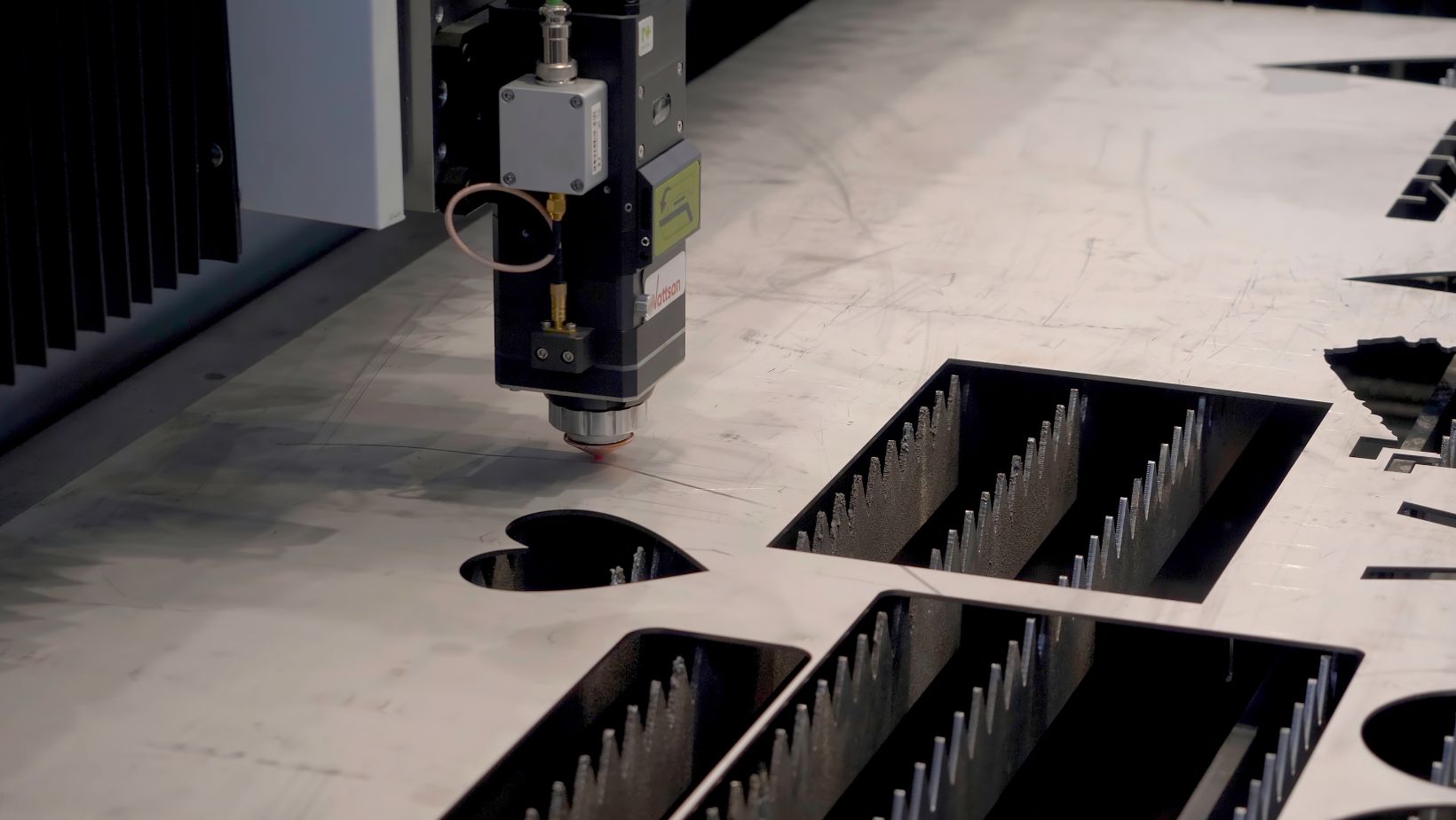

Another powerful option, the xTool P2, is a CO₂ laser that offers a higher power output, making it effective for cutting thicker wood with industrial-grade precision—ideal for larger-scale or professional projects.

For those working from home or in smaller spaces, the xTool M1 is a compact and versatile choice that handles wood and other materials with ease, perfect for DIY projects and small businesses. Choosing the right machine, like the laser cutters available from xTool, allows users to achieve professional-quality results efficiently and expand the types of wood projects they can pursue.

Essential Settings for Cutting and Engraving Wood

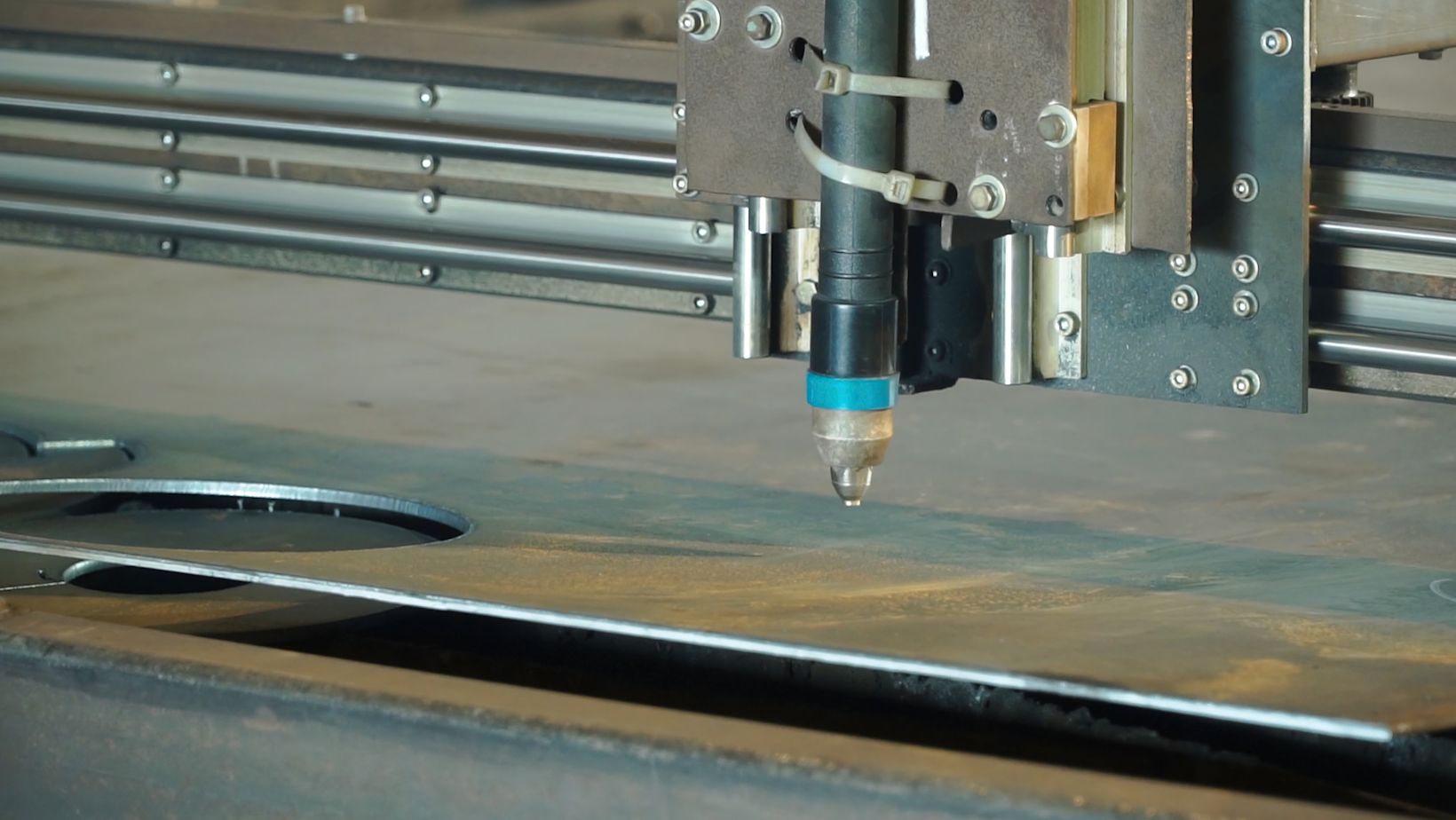

To achieve the best results, understanding key laser settings is essential. Laser power is the first setting to consider, as higher power levels are needed for thicker or denser wood types, while softer woods or thin veneers can be handled with lower power settings.

Speed settings are also important; slower speeds allow for deeper, cleaner cuts, but going too slow can increase the risk of burning the wood. Finding a balance between speed and power is key for achieving clean cuts without scorch marks.

Focusing and adjusting the resolution are other critical factors. Ensuring the laser is correctly focused on the wood’s surface results in cleaner lines and edges while adjusting the resolution, measured in DPI, allows for more detailed engraving.

Many laser cutters come with pre-set options for different wood types, which can be an excellent starting point, especially for those new to laser cutting. Experimenting with these settings on scrap pieces of wood is a practical way to understand the nuances and find the ideal configuration for each project.

Safety Tips for Laser Cutting Wood

Safety should always be a priority in laser cutting, especially with flammable materials like wood. Proper ventilation is crucial since wood cutting produces smoke and fumes; an exhaust system or well-ventilated workspace is essential to avoid exposure to potentially harmful particles. Wearing protective gear, such as safety glasses, is also highly recommended, particularly with high-powered lasers, to prevent accidental exposure to beam reflections.

Fire safety is another major consideration, as wood is naturally combustible. Keeping a fire extinguisher close by and never leaving the laser cutter unattended during operation are necessary precautions. Following these safety tips minimizes risks and helps ensure a productive laser-cutting experience.

Creative Project Ideas Using Wood Laser Cutting

Laser cutting opens up endless creative possibilities for wood projects. Many people use laser cutting to create unique home décor, such as intricately designed wall art, custom wooden coasters, or even decorative table runners. Personalized gifts are another popular category; engraved photo frames, custom keychains, or wooden puzzles are thoughtful, unique items that make excellent gifts.

For those interested in starting a business, laser-cut products like wooden signs, jewelry, and phone cases are popular on e-commerce platforms like Etsy and Amazon Handmade, offering a variety of small business opportunities.

Furniture accents are another unique use, where laser-cut veneer inlays or engraved patterns can add a distinctive flair to furniture pieces. Whether for personal enjoyment or business purposes, wood laser cutting offers endless avenues for creativity and customization.

Maintenance and Care for Your Laser Cutter

Proper maintenance is key to extending your laser cutter’s lifespan and ensuring consistent quality. Regular cleaning is a must, as wood cutting produces dust and residue that can build up on the machine’s lenses and mirrors, obstructing the laser and reducing precision. Keeping these components clean will help maintain clear, precise cuts.

Laser alignment is another essential aspect of maintenance. Ensuring that the laser beam is correctly aligned helps avoid uneven cuts or reduced power. For CO₂ lasers, proper cooling is also necessary to prevent overheating, and occasionally lubricating moving parts can keep the machine running smoothly. Following these maintenance practices will help keep your laser cutter in optimal condition, allowing you to continue creating high-quality wood projects for years to come.

Conclusion

Laser cutting wood offers countless creative opportunities, whether you’re a DIY enthusiast, hobbyist, or small business owner. With the right tools, settings, and maintenance, anyone can achieve professional-quality results on a range of projects. Laser cutting combines efficiency and precision, enabling users to bring intricate, customized designs to life. From selecting the best wood type to understanding essential settings, safety precautions, and maintenance tips, this guide covers everything you need to make the most of your laser-cutting experience. If you’re ready to explore more, visit xTool’s laser cutting resources for additional insights and tools to support your wood laser cutting journey.