It is challenging to imagine a production or business that does not use modern technologies today. Finding a direction where modern technologies are not used is problematic. We can see how owners of multiple industries also actively use AI in their work.

Using industry-specific ai solutions helps improve product quality, reduce costs, and increase competitiveness. Today, it is challenging to thrive without using modern technologies. Therefore, industry owners who want to survive and expand resort to AI.

Table of Contents

ToggleMain Tasks of AI in Manufacturing

Artificial intelligence tools help production owners solve various problems:

- automation of production processes;

- predictive equipment maintenance;

- optimization of supply chains;

- personalization of production.

Let’s consider each aspect in more detail. You will understand how artificial intelligence tools can help your production. Business owners can choose suitable implementations to adapt their work to modern realities and requirements.

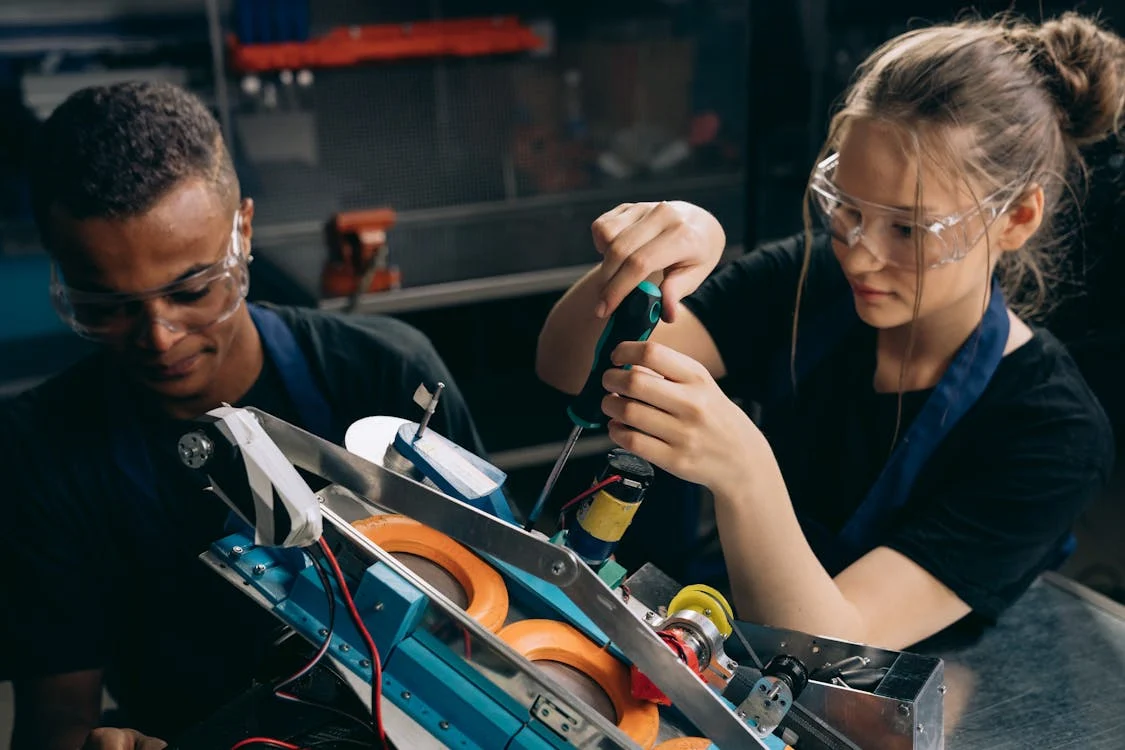

Automation of Manufacturing Processes

Artificial intelligence is used in various areas of industry, and automation of manufacturing processes is no exception. Modern systems can perform complex tasks with minimal human intervention, thanks to AI. You can use robotic systems that can perform the following functions:

- assemble products;

- check the quality of goods;

- manage logistics at the plant.

This approach will reduce the likelihood of erroneous actions, increase productivity, and speed up various processes.

Automation helps enterprises better perform tasks that require high precision and constant control. Artificial intelligence is critical in the automotive industry or microelectronics because, in these areas, the slightest mistake can cause significant losses.

Predictive Equipment Maintenance

Artificial intelligence-based systems can analyze data on the operation of machines, machines, and mechanisms. You will be able to receive information about possible malfunctions. Such information allows you to fix problems and issues before they occur. Enterprises can schedule maintenance at a convenient time. Due to emergencies, you will not have to stop production at the most inopportune moment.

You don’t have to collect data from equipment sensors and detectors yourself. Now, predictive maintenance systems perform such functions. Artificial intelligence tools analyze the received information, compare it with historical data, and identify possible anomalies. This is how possible breakdowns are determined.

Enterprises can replace worn parts or perform repairs in advance for production efficiency. This approach helps increase equipment’s service life and reduce overall operating costs.

Supply Chain Optimization

Without artificial intelligence, supply chains would not be as efficient. Companies are tasked with managing their supplies to minimize risks and optimize costs. Such innovations are needed in globalization and constantly changing market conditions. AI tools analyze vast amounts of data on:

- demand;

- supply;

- logistics;

- other factors.

Don’t spend much time correctly identifying the elements that affect the supply chain. Artificial intelligence can perform such tasks quickly and correctly.

The use of artificial intelligence in this area helps to solve many problems, namely:

- forecast demand;

- optimize inventory levels;

- plan deliveries, taking into account various factors.

Business owners can avoid a situation with a shortage or surplus of products, which negatively affects the business.

Personalization of Production

Various artificial intelligence tools provide such opportunities. Traditional industries have stopped producing large volumes of goods, and we can see the release of large batches of identical products.

The use of AI allows companies to adapt their production processes to the individual needs of customers. Artificial intelligence quickly analyzes customers’ wishes and preferences. In the second stage, a relevant offer is created for potential buyers. Users can get a vehicle based on their personal preferences in the following areas:

- color;

- equipment;

- additional options;

- other parameters.

Thus, you can increase customer satisfaction. Companies can use resources efficiently and shock production to meet real market needs.

What Opportunities Does AI Provide in Industry

The use of artificial intelligence in industry has many positive qualities. Let’s consider the key advantages:

- increased productivity — by automating complex processes, you can reduce costs and increase the speed of individual operations;

- improved product quality — AI provides precise quality control at each production stage, so you can minimize the likelihood of defects or the production of defects;

- reduced costs — production owners will be able to reduce operating costs, and process optimization, predictive maintenance, and personalization facilitate this;

- adaptability to change — artificial intelligence tools can quickly respond to changes in market conditions, making the company more flexible and competitive;

- innovation — the introduction of AI stimulates the development of new technologies, and you connect new production methods, opening up new opportunities for business development.

As noted, artificial intelligence’s introduction in production is accompanied by several positive indicators and characteristics. Your task is to use the provided opportunities correctly.

Conclusion

Artificial intelligence is significantly impacting the industry. It is transforming manufacturing processes and creating new business opportunities. RapidCanvas’ turnkey AutoAI solutions are tailored to your needs and aim to increase your business’s efficiency and success.

To achieve the desired results, you must carefully approach AI implementation. Successful implementation is accompanied by processes such as data analysis, process adaptation, and staff training. Modern tools will only give the desired effect with such a preparatory stage.