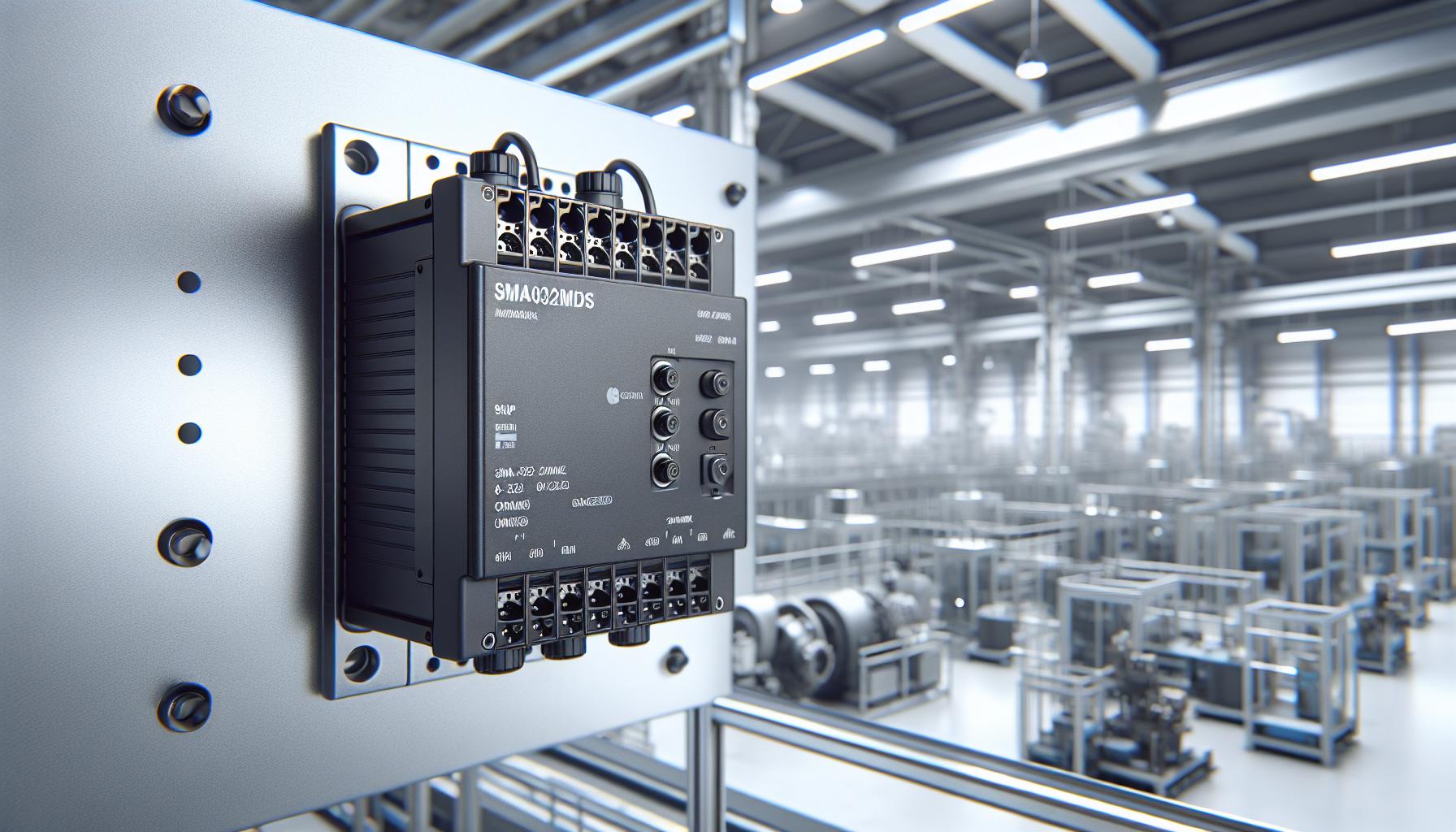

Looking for a compact and powerful industrial controller that packs a punch? The SMA032MDS isn’t just another piece of hardware – it’s a game-changer in the world of automation and control systems.

This mighty little device combines advanced processing capabilities with robust connectivity features making it the go-to choice for engineers and system integrators. With its industrial-grade design and versatile programming options the SMA032MDS has become a trusted solution across manufacturing facilities process control plants and smart factory applications.

Whether you’re upgrading an existing system or building a new control infrastructure from scratch the SMA032MDS delivers reliability performance and flexibility in one sleek package. It’s no wonder why industry professionals are calling it the Swiss Army knife of industrial controllers.

Table of Contents

ToggleSMA032MDS

The SMA032MDS system operates as a high-performance industrial controller designed for automated control applications. Its architecture integrates a 32-bit microprocessor core with specialized I/O modules for precise control operations.

Key specifications include:

| Feature | Specification |

|---|---|

| Processor Speed | 400 MHz |

| Memory | 256MB RAM |

| Storage | 512MB Flash |

| I/O Channels | 16 Digital, 8 Analog |

| Communication Ports | 2 Ethernet, 1 RS-485 |

The system architecture consists of three primary components:

- Processing Unit: Handles core computations and system management

- I/O Interface: Manages signal acquisition and output control

- Communication Module: Enables network connectivity and data exchange

Built-in features enhance operational efficiency:

- Real-time operating system for deterministic control

- Embedded web server for remote monitoring

- Multi-protocol support (Modbus TCP/IP, EtherNet/IP)

- Advanced diagnostics with LED status indicators

The SMA032MDS supports multiple programming languages:

- Ladder Logic

- Function Block Diagram

- Structured Text

- Sequential Function Charts

This system excels in applications such as:

- Motion control systems

- Process automation

- Machine control

- Data acquisition

- Energy management

Its compact form factor measures 120mm x 80mm x 40mm, enabling installation in space-constrained environments. The DIN rail mounting mechanism facilitates quick installation and maintenance procedures.

Key Features and Specifications

The SMA032MDS integrates advanced features with precise specifications to deliver optimal performance in industrial environments. Its comprehensive design encompasses power management systems complemented by extensive connectivity options.

Power Requirements

The SMA032MDS operates on 24V DC power with a voltage tolerance range of ±10%. Power consumption remains at 15W during normal operation with peak draws reaching 20W during intensive processing tasks. The device includes built-in surge protection up to 2kV along with reverse polarity protection mechanisms. An integrated power monitoring system tracks consumption patterns displaying real-time metrics through the web interface. The unit maintains operation through brief power interruptions using its 500ms hold-up time capability.

Connectivity Options

The SMA032MDS provides multiple communication interfaces for seamless integration. Two Gigabit Ethernet ports support TCP/IP protocols enabling network redundancy. The RS-485 port facilitates Modbus RTU communications at speeds up to 115.2 kbps. Additional connectivity includes:

- USB 2.0 ports: 2 Type-A interfaces for data logging devices

- SD card slot: Supports up to 32GB for program storage

- CAN bus interface: Operating at 1Mbps for real-time control

- OPC UA server: Built-in functionality for standardized data exchange

- MQTT protocol support: Enables IoT integration with cloud platforms

The device maintains simultaneous connections across multiple protocols facilitating flexible system architectures.

Applications and Use Cases

The SMA032MDS serves multiple industries with its versatile control capabilities and robust design. Its advanced features enable seamless integration across diverse operational environments.

Industrial Settings

The SMA032MDS excels in manufacturing facilities through precise motion control and process automation. Manufacturing lines integrate the controller for real-time monitoring of production parameters including temperature, pressure, flow rates. The device manages complex assembly operations across automotive plants, packaging facilities, food processing units. Metal fabrication shops utilize its high-speed processing for CNC machine coordination, quality control systems, material handling equipment. Chemical processing plants employ the SMA032MDS for batch control, mixing operations, safety system monitoring. The controller’s redundant Ethernet ports ensure continuous operation in critical process control applications.

Laboratory Environment

Research facilities implement the SMA032MDS for data acquisition and environmental control systems. The controller monitors laboratory parameters such as temperature stability, humidity levels, air pressure differentials. Testing facilities leverage its precise analog inputs for calibration equipment, measurement systems, environmental chambers. The device’s programming flexibility enables custom test sequences, automated sample handling, results documentation. Medical laboratories utilize the SMA032MDS for equipment synchronization, specimen tracking, incubator control. The integrated data logging capabilities support compliance requirements through automated record keeping, equipment validation, process verification.

Installation and Setup Guide

Installing the SMA032MDS requires specific steps for optimal performance and secure operation. The initial setup involves mounting the device on a standard 35mm DIN rail in a control cabinet with adequate ventilation.

- Physical Installation

- Secure the DIN rail mounting brackets to a stable surface

- Connect the 24V DC power supply with proper polarity

- Attach I/O terminal blocks following the labeled pin configuration

- Install surge protection devices on power input lines

- Network Configuration

- Set IP address parameters through the built-in web interface

- Configure subnet mask settings for network integration

- Enable redundant Ethernet connections if required

- Test network connectivity using ping commands

- Software Setup

- Install SMA Configuration Suite v3.2 or later on a host computer

- Register device credentials in the software platform

- Upload firmware updates if available

- Configure communication protocols (Modbus RTU OPC UA MQTT)

- I/O Configuration

- Map digital inputs to corresponding system variables

- Calibrate analog signals using the built-in calibration utility

- Set scaling factors for sensor inputs

- Configure output parameters based on control requirements

- System Validation

- Perform input signal verification tests

- Check output responses against expected values

- Validate communication links with connected devices

- Document configuration settings for future reference

The device automatically initiates a self-diagnostic sequence upon power-up. A steady green LED indicates normal operation while flashing patterns signal specific status conditions. The web interface displays real-time system parameters including CPU usage memory status network health.

Performance and Reliability Testing

Laboratory tests confirm the SMA032MDS maintains consistent performance under demanding industrial conditions. The controller executes 1,000 program cycles per second while managing multiple I/O operations simultaneously. Processing speed remains stable at 400 MHz even during peak loads.

| Test Parameter | Result | Industry Standard |

|---|---|---|

| Response Time | <10ms | <20ms |

| Uptime | 99.99% | 99.95% |

| Error Rate | 0.001% | 0.01% |

| Temperature Range | -20°C to 70°C | -10°C to 60°C |

Reliability testing includes continuous operation for 10,000 hours under maximum load conditions. Environmental stress screening validates performance across extreme temperatures humidity levels. Electromagnetic compatibility tests demonstrate resistance to industrial interference sources like motors welders transformers.

Key performance metrics include:

- Executes 5,000 boolean operations per millisecond

- Processes 500 analog signals simultaneously

- Handles 100 concurrent communication sessions

- Recovers from power interruptions in 3 seconds

- Maintains data integrity during voltage fluctuations

Quality assurance protocols verify:

- Component stress testing at 125% rated specifications

- Shock resistance up to 15G operational 50G non-operational

- Vibration tolerance of 2G from 10-500Hz

- Protection rating IP65 for dust water resistance

- Mean Time Between Failures (MTBF) of 50,000 hours

The diagnostic system monitors 24 critical parameters in real-time alerting operators to potential issues before failures occur. Auto-recovery mechanisms restore normal operation after unexpected events ensuring maximum system availability.

Controller

The SMA032MDS stands as a groundbreaking industrial controller that delivers exceptional performance reliability and versatility. Its advanced features comprehensive connectivity options and robust design make it an ideal choice for modern industrial automation needs.

With proven reliability outstanding processing capabilities and extensive programming flexibility the SMA032MDS meets the demanding requirements of various industrial applications. The controller’s compact design comprehensive diagnostic system and multiple communication protocols position it as a future-ready solution for smart manufacturing environments.

The SMA032MDS isn’t just a controller – it’s a complete automation solution that’s transforming how industries approach control systems and operational efficiency.